7 Axis CNC Means, Contemporary production is moving in the direction of better precision and more complicated designs. conventional machines with 3 axes are no longer sufficient for many superior parts. This is in which multi-axis CNC technology comes in.

Whilst humans ask what 7 axis CNC manner, they’re talking approximately a pretty advanced sort of CNC device which can pass and cut in seven one-of-a-kind instructions or actions at the same time. This lets in manufacturers to create extraordinarily complicated shapes in a single setup with out preventing or manually repositioning the part.

In this text, you will examine what a 7-axis CNC gadget is, the way it works, how it is distinctive from other machines, and where it’s miles used in actual industries.

Basic Idea of CNC Axes

Earlier than know-how 7 axes, it’s miles essential to know what an “axis” method in CNC machining.

An axis is a path wherein the slicing device or the workpiece can move.

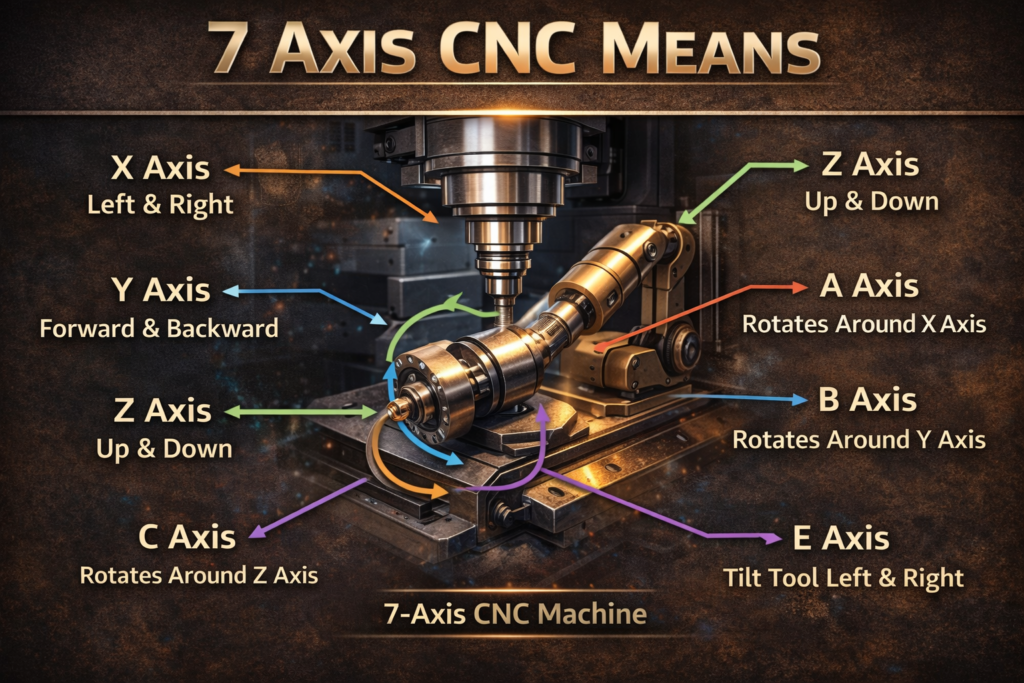

The three fundamental linear axes are:

- X axis: Left and proper

- Y axis: Forward and backward

- Z axis: Up and down

These three axes are used in standard 3-axis CNC machines.

From 3 Axis to Multi-Axis Machining

To create more complex shapes, extra movements are added.

These extra movements are rotations around the basic axes.

| Axis Name | Type of Movement | Description |

|---|---|---|

| A axis | Rotation around X | Tilts the part or tool |

| B axis | Rotation around Y | Angles the part or tool |

| C axis | Rotation around Z | Spins the part like a turntable |

Machines can also include extra linear or rotational movements for special tasks.

What 7 Axis CNC Means in Simple Words

A 7-axis CNC device combines:

- Three linear actions (X, Y, Z)

- Three rotational actions (A, B, C)

- 1 extra movement, regularly a second spindle, tool slide, or workpiece rotation system

This 7th axis offers greater freedom to approach the element from greater angles without eliminating it from the gadget.

In easy terms, it approach:

The gadget and the component can pass in seven extraordinary ways on the identical time to reduce very complex shapes as it should be.

How a 7 Axis CNC Machine Works Step by Step

Step 1: Part Design

- An in depth three-D version is created in CAD software.

- All curves, holes, and angles are defined.

Step 2: Toolpath Programming

- CAM software program calculates how the slicing tool need to flow.

- All seven axes are coordinated within the software.

Step 3: Device Setup

- The uncooked material is fixed once within the system.

- Multiple gear are loaded into the automatic device changer.

Step 4: Simultaneous Machining

- The system moves and rotates the element and tool collectively.

- Complex capabilities are reduce from many instructions in one cycle.

Step 5: finishing and Inspection

- Final passes create clean surfaces.

- Precision measuring gear take a look at the scale.

Due to the fact everything happens in one setup, accuracy is very high.

Difference Between 3, 5, and 7 Axis CNC

| Feature | 3 Axis CNC | 5 Axis CNC | 7 Axis CNC |

|---|---|---|---|

| Basic movements | X, Y, Z | X, Y, Z + 2 rotations | X, Y, Z + 3 rotations + extra axis |

| Part repositioning | Needed many times | Rarely needed | Almost never needed |

| Complex shapes | Limited | Very good | Excellent |

| Setup time | High | Medium | Low |

| Accuracy on complex parts | Medium | High | Very high |

| Typical use | Simple parts | Aerospace, medical | Ultra-complex and multi-side parts |

Main Benefits of 7 Axis Machining

Using a 7-axis system gives many advantages.

- Machine complicated parts in a single setup

- Higher precision because the part isn’t moved

- Quicker manufacturing for specific additives

- Better surface end on curved areas

- Capability to reach hidden or angled features

- Reduced want for unique fixtures

This saves both money and time in high-give up manufacturing.

Common Applications of 7 Axis CNC

7-axis machines are used where regular machines cannot reach all regions without problems.

Normal industries include:

- Aerospace turbine additives

- Clinical implants and surgical gear

- Car racing parts

- Complicated molds and dies

- Robotics and automation components

- Defense and precision engineering

Those elements regularly have curves, deep pockets, and angled holes.

Types of 7 Axis CNC Configurations

Not all 7-axis machines are constructed the same way.

A few common setups are:

- Mill-turn machines with spindles and a rotating tool head

- Robotic arm CNC structures with more than one joints

- Sliding headstock lathes with extra rotary axes

Every design is made for precise element types.

Advantages Compared to Multiple Setup Machining

| Aspect | Multiple Setups on Simple CNC | Single Setup on 7 Axis CNC |

|---|---|---|

| Time needed | Long | Short |

| Risk of error | Higher | Very low |

| Alignment accuracy | Can shift each setup | Perfectly maintained |

| Labor effort | High | Lower |

| Surface quality | May vary | Consistent |

Single setup machining is the biggest strength of 7 axes.

Programming Challenges and Solutions

Programming seven axes is greater complex than programming three.

Demanding situations:

- Toolpath calculation is more difficult

- Hazard of collision is higher

- Requires advanced CAM software

Solutions:

- Use simulation before actual slicing

- Apply automated collision detection

- Use skilled CNC programmers

Cutting-edge software program makes multi-axis programming easier than before.

Tooling and Accessories Used

7-axis machines often use unique equipment.

- Lengthy reach stop turbines

- Ball nose cutters for curved surfaces

- Multi-directional cutting heads

- Automatic tool changers with many gear

Those tools help attain each attitude of the part.

When Should You Use a 7 Axis CNC?

A 7-axis gadget is not usually important.

It’s far best whilst:

- The part has very complicated geometry

- Many aspects should be machined without delay

- Extremely excessive precision is needed

- Production time must be reduced

- Manual repositioning would be tough

For easy flat parts, a 3-axis device is enough.

Cost Considerations

7-axis machines are more steeply-priced than trendy CNC machines.

But, they are able to reduce normal production cost by way of:

- Reducing setup time

- Reducing guide exertions

- Averting unique furnishings

- Lowering rejection fees

For high-cost components, the funding is frequently worth it.

Future of Multi-Axis CNC Technology

Manufacturing is transferring toward more automation and versatility.

Destiny improvements may include:

- AI-assisted toolpath optimization

- Fully automated loading and unloading

- Smarter real-time error correction

- Integration with digital twin simulation

This can make advanced machining faster and more secure.

FAQs

Is 7 axis better than 5 axis?

For extremely complex components, sure. It gives greater movement and flexibility.

Can a 7 axis machine replace other machines?

In a few superior workshops, it can carry out many operations that would typically want numerous machines.

Is programming difficult?

It is more complicated, but current CAM software program allows lots.

Are these machines most effective for massive factories?

In the main used by excessive-give up producers, however smaller precision stores also use them for special jobs.

Does it enhance surface finish?

Sure, due to the fact the device can stay at the satisfactory slicing attitude all of the time.

Is it suitable for mass production?

Yes, specially for complex parts wherein one-setup machining saves time.

Conclusion

Knowledge what 7 axis CNC approach facilitates explain how current factories create fantastically complex and specific parts. Via combining more than one linear and rotational movements with an extra axis, those machines can reduce almost any form in a unmarried setup.

They lessen mistakes, enhance accuracy, and shop production time. while they are greater high-priced and require advanced programming, their advantages are big for industries like aerospace, medical, and excessive-precision engineering.

As era keeps to grow, 7-axis CNC machining will play a good larger role in constructing the complex merchandise of the future.